ApplicationApplication

about usabout us

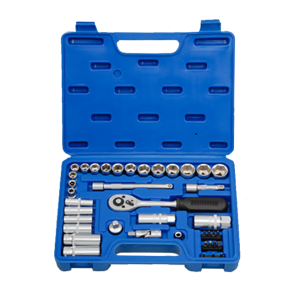

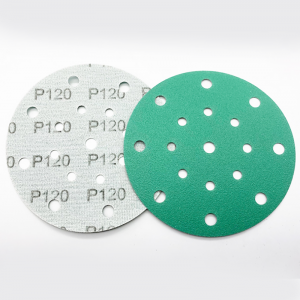

Our company is a leading manufacturer and exporter of tools, committed to providing the finest quality at competitive prices. We have a large selection of cutting tools, hand tools, as well as abrasive products available at guaranteed lowest prices to help you get all of your construction projects done on time and within budget. Our Mission To be the most valued supplier of cutting tools and abrasive products to customers, we provide the highest levels of product quality, service, and expertise.

Featured productsFeatured products

ProductsProducts

latest news

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WW

-

WeChat

-

Top